PCB FOR MEDICAL DEVICES

MEDICAL DEVICES PCB

BD Star worked with over 1,595 customers all over the world in the telecom, 3G product, RF, security, industrial, medical and hi-tech industries.

We have an experienced engineer team that always available to discuss your requirements.

Testimonials

Sub heading

Metal Core PCB

- LED-based medical

- lighting high-power density applications

- medical devices requiring effective heat dissipation.

FR-4 PCB

- General-purpose medical devices

- Patient monitoring equipment

- Laboratory instruments

- Infusion pumps

High-Temperature PCB

- Diagnostic imaging equipment (MRI, CT scanners)

- Devices with high-temperature requirements.

Flexible PCB

- Wearable medical devices

- Medical sensors

- Conformal and flexible electronics in patient monitoring.

Importance Of Medical Device PCB Production

As one of the leading electronic PCBA suppliers in China, we have over 17 years of experience in providing one-stop OEM services.

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

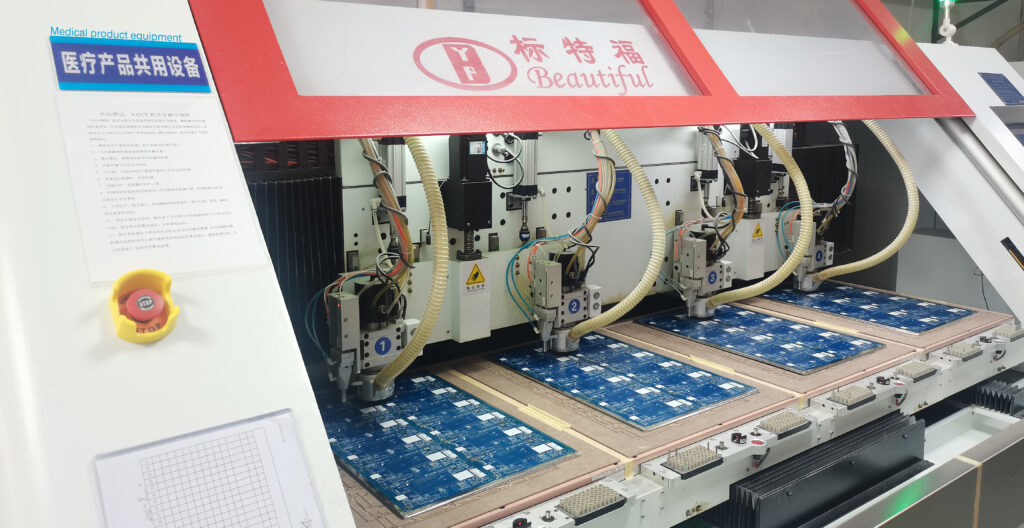

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.

In summary

BD Star worked with over 1,595 customers all over the world in the telecom, 3G product, RF, security, industrial, medical and hi-tech industries.

We have no MOQ requirement. Call us today to learn more details.

Related Products

About Bd Star (shenzhen) Industry Co., Ltd.

Various circuit board types such as rigid PCB, flexible PCB, rigid-flex PCB, copper PCB and high density interconnect PCB are all available.

We have an experienced engineer team that always available to discuss your requirements.

- Complete certificates, professional ISO management system.

- Advanced production equipment, strict quality inspection process

- Wide range of pcb's, mass production and fast delivery.

Welcome to ask us if your have any related questions.